Introduction

In the world of modern technology, ensuring a reliable power supply is crucial for the successful operation of various industries. One key component in achieving this reliability is the diesel generator. Diesel generators play a vital role in providing backup power during outages and are essential for site acceptance testing of critical infrastructure. In this article, we will explore the significance of diesel generators in site acceptance testing and discuss their features, benefits, and best practices for ensuring their optimal performance.

Importance of Diesel Generators in Site Acceptance Testing

Site acceptance testing is a critical phase in the installation and commissioning of various systems and infrastructure, such as telecommunications networks, data centers, hospitals, and industrial facilities. During this phase, the performance and functionality of the site are evaluated to ensure that it meets the specified requirements and standards. One of the key requirements for successful site acceptance testing is the availability of a reliable power supply.

Diesel generators are widely used in site acceptance testing due to their ability to provide backup power in the event of utility power outages or disruptions. These generators are capable of quickly starting up and supplying power to critical systems, ensuring that the testing process continues uninterrupted. In addition, diesel generators can operate for extended periods of time, making them ideal for prolonged testing procedures that require continuous power supply.

Features of Diesel Generators

Diesel generators are designed to convert diesel fuel into electrical energy through a combustion process. They consist of several key components that work together to generate and deliver power. Some of the main features of diesel generators include:

1. Engine: The engine is the heart of the diesel generator and is responsible for converting the chemical energy of diesel fuel into mechanical energy. Diesel engines are known for their durability, efficiency, and reliability, making them well-suited for backup power applications.

2. Alternator: The alternator is the component that converts the mechanical energy generated by the engine into electrical energy. It consists of a rotor and a stator that work together to produce an alternating current (AC) output.

3. Fuel System: Diesel generators require a fuel system to store and deliver diesel fuel to the engine for combustion. The fuel system includes a fuel tank, fuel lines, fuel pump, and fuel injectors.

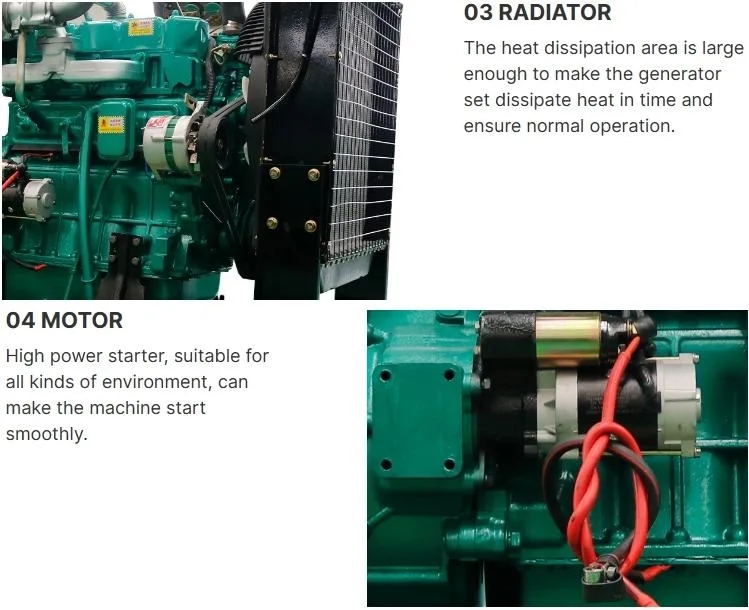

4. Cooling System: Diesel engines generate heat during operation, which must be dissipated to prevent overheating. The cooling system of a diesel generator typically consists of a radiator, cooling fan, and coolant circulation system.

5. Control Panel: The control panel is the interface through which the operator can monitor and control the operation of the diesel generator. It provides information on key parameters such as voltage, frequency, and engine status, and allows for manual or automatic control of the generator.

Benefits of Diesel Generators in Site Acceptance Testing

The use of diesel generators in site acceptance testing offers several benefits that contribute to the overall success of the testing process. 200kw diesel generator for remote manufacturing of the key benefits of diesel generators include:

1. Reliability: Diesel generators are known for their reliability and robust performance, making them a dependable source of backup power for critical applications. They can start up quickly and provide stable power output, ensuring uninterrupted testing operations.

2. Versatility: Diesel generators are versatile power sources that can be easily transported and deployed in various locations. This flexibility allows for testing to be conducted in remote or temporary sites where utility power may not be available.

3. Longevity: Diesel generators are designed to operate for extended periods of time without compromising performance. This longevity is essential for site acceptance testing procedures that require continuous power supply over extended durations.

4. Fuel Efficiency: Diesel engines are known for their fuel efficiency, consuming less fuel compared to other types of generators while delivering high power output. This efficiency helps reduce operating costs and ensures cost-effective testing operations.

Best Practices for Diesel Generator Performance in Site Acceptance Testing

To ensure the optimal performance of diesel generators in site acceptance testing, it is important to follow best practices that help maximize their efficiency and reliability. Some of the key best practices for diesel generator performance include:

1. Regular Maintenance: Scheduled maintenance is essential to keep diesel generators in top condition and prevent unexpected failures during testing. Regular maintenance tasks include checking fluid levels, changing filters, inspecting belts and hoses, and testing battery condition.

2. Fuel Quality: The quality of diesel fuel used in generators can impact their performance and longevity. It is important to use high-quality fuel that meets the manufacturer's specifications and to monitor fuel storage conditions to prevent contamination.

3. Load Testing: Periodic load testing of diesel generators is crucial to ensure that they can handle the required load during site acceptance testing. Load testing helps identify any issues with the generator's capacity and performance under varying load conditions.

4. Remote Monitoring: Implementing remote monitoring systems allows operators to track the performance of diesel generators in real-time and receive alerts in case of any issues or anomalies. Remote monitoring helps prevent downtime and enables proactive maintenance.

5. Training and Documentation: Providing training to operators on the proper operation and maintenance of diesel generators is essential for ensuring their optimal performance. Maintaining detailed documentation of maintenance procedures, service records, and test results helps track the history of the generator and identify trends or patterns.

Conclusion

Diesel generators play a crucial role in site acceptance testing by providing reliable backup power for critical systems and infrastructure. Their robust performance, versatility, and efficiency make them an essential component of testing procedures that require continuous power supply. By following best practices for diesel generator performance, operators can ensure that these generators operate at their best and contribute to the success of site acceptance testing. Investing in high-quality diesel generators and implementing proper maintenance and monitoring procedures are key steps towards achieving a reliable power supply for testing operations.